Extrusion, Heat forming technology

In making full use of accumulated technical know-how and the "material" that was properly selected, we have been trying to maximize our manufacturing and developing capability with providing best efficient "extruded" solution and exactly "processed" product as requested by customer.

We are working in good faith to realize technological innovation and quality stabilization to bring customer's requirements and satisfaction.

Our extrusion technology provides a fine capillary of micro-unit and Heat forming technology creates three-dimensional network fine capillary structure. These technologies are highest level worldwide. With these unique nib production systems, our continuous development efforts can lead to creative new product and application developments ever.

We are more than happy to offer consultation for problem solving and looking forward to offer co-development and technical and analysis support.

Precision extrusion technology

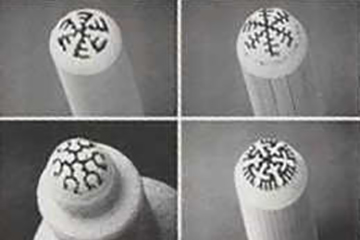

Our precision extrusion technique can make a complexed micro-sized design in the 0.8 mm core diameter plastic tube. (see left : flow path)

Our extrusion technique can utilize engineering plastics for drawing pen nib, polyester elastomer for calligraphy pen nib, polypropylene especially used for the medical liquid feeding tube.

Also, it is possible to extrude tubes coated with plastic or colored coating material.

Fiber forming

(three-dimensional mesh structure micro capillary)

Crimp: When forming a bundle of fibers with (crimped fibers), the inside of the material rod body, will be three-dimensional network structure with entangled fibers to the front, rear, left and right. The fine network structure creates a strong capillary force, plays a role in attracting the foreign matter as a filter.

Selection of a various number of types and fiber dimensions can adjust the three-dimensional network structure very fine.

In addition, the hardness, elasticity of the fiber rod material body also, can be adjusted upon request. Our fiber nib technology can make a wide selection of the porosity, strength and durability.

Injection molding

The injection molding, the manufacturing method commonly used in plastic molding, push the material heated and melted at a temperature to soften the material by adding injection pressure is a way of obtaining a molded article by which cooled and solidified. This technology is mainly used in the case of molding a three-dimensional plastic products.

We are engaged in the manufacture of medical-related products including small-lot production which is our specialty field.

Specific Applications

-

With the elastomer employed in material developed especially suitable for precision extrusion, we developed fine stylus pen nib which realizes a similar moderate resistance and a smooth writing feeling as when written on paper. You can enjoy comfortable writing performance with durability and resilience.

-

Our heating technology can separately form hard outer periphery and softer center part of the material rods at the same time. This unique production technology developed special brush nibs in which both a hard outer periphery of the holding portion and a soft writing portion of the centers are integrated.

-

AuBEX MEDICAL Inc. is a medical device manufacturing facility of AuBEX Group. As a part of production site for a pressurized pharmaceutical injector for chemotherapy, we have also performed the manufacture of parts by injection molding.

Taking advantage of these know-how that we have piled up, we are pleased to provide better service for the customers to solve troubled issues and technical problems.

- TOP

- TECHNICAL INFORMATION

- Extrusion, Heat forming technology

Copyright(C) AUBEX CORPORATION All rights reserved.