Processing technology

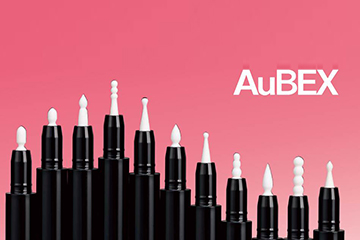

We are supplying high-value-added products created from the materials which are originally used for pen nibs, cosmetic nibs and for medical equipment with increasing the value by the sophisticated processing technology to a wide range of genres.

Processing technology cultivated in this, not only the material produced in our company, is processed to target a variety of materials, we are considered to have the potential to lead to high-value-added products further.

For technical improvement as well as problem-solving for customers, we will be happy to support such as joint research and technology and analysis.

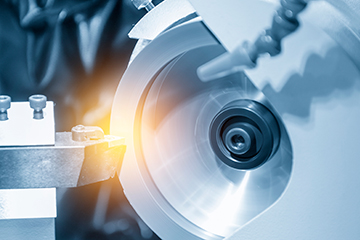

Precision grinding

Precision grinding technology is to curve out the defined shape with grinding off the surface of the target material with spinning grinding stone.

Our grinding technology with tremendous and long term experience in the nib industry can meet the various needs of customers. We are confident that especially for grinding accuracy of the soft porous material has the top level of grinding capability in the industry.

Punching processing

If the workpiece is a flat plate, punching or stamping is a good choice. Punching processing is to stamp out the required shape through die from flat plate material.

Our punching technique is suitable not only for processing of particularly small area and but also for processing of the required shape.

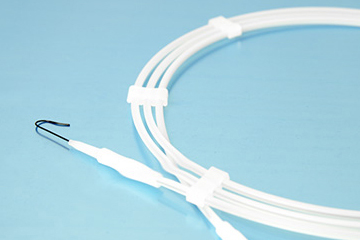

EOG sterilization

We are engaged in the manufacture and sale of medical products, such as vessel fusser (infuser) and guide wire. For the sterilization process, We are utilizing the EOG sterilization equipment at the medical device manufacturing facilities.

EOG sterilization, refers to the method of killing microorganisms by distributing mainly ethylene oxide gas directly.

In addition to the medical equipment in recent years, to the sterilization of cosmetic applicators are also our EOG sterilization is used. We are expanding the field of business with this facility.

Wettability control

(hydrophilic coating)

On the surface of our guide wire to be inserted into the blood vessels, it has been subjected to a hydrophilic coating to improve the slip properties of the surface. Hydrophilic coating layer on the surface has a high sliding property when it has wettability and it features the different movement of slipperiness depending on wettability of coating surface.

Our hydrophilic coating is capable of coating on the shape other than a wire-like and also is proven high safety technology as the advanced controlled medical devices.

In addition to the hydrophilic technology, we are also working on technology to make the surface water-repellent.

Conductive treatment

Coating the surface with a conductive layer will make non-conductive objects electrically conductive. Making objects electrically conductive reduces static electricity and allows electricity to pass through the object.

Specific use examples

By taking advantage of these processing technology, we have been working on to increase a variety of high value added product development.

Here are the specific examples below.

-

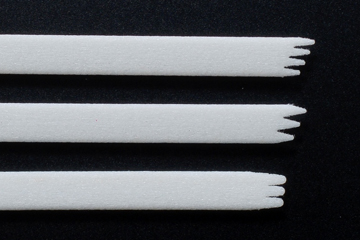

Our fiber forming production technology can make maximum diameter of 12 mm cylindrical porous body and minimum 0.4mm cylindrical porous body which is available for various applications including writing and cosmetics application. Our plastic extrusion technology can make a diameter of 0.4 mm which can be used for writing instruments and other applications.

We have a line up of a wide variety of materials which have different stiffness from soft to hard. Our precision grinding techniques can process particularly soft and porous material with high accuracy. -

Our EOG sterilization is widely used in medical devices industry.

We can also use this facility to sterilize the cosmetic tip and other products.

In the case of minute products we put them into the special sterilization bag to sterilize.

If you have any demand of sterilization to medical equipment, pen nib, cosmetic nib and other components you use, please contact us. -

In applications such as a smartphone, a tablet, our conductive treated stylus pen tip is adopted as device to detect the touching point location by detecting a weak current.

Since conductive treatment is actually made to the nib of standard writing pen, we can reproduce the similar writing feeling for the stylus writing on the display.

Taking advantage of these know-how that we have piled up, we are pleased to provide better service for the customers to solve troubled issues and technical problems.

- TOP

- TECHNICAL INFORMATION

- Processing technology

Copyright(C) AUBEX CORPORATION All rights reserved.